Reliable Ammonia Catalyst Solution

- Technology leadership

Continuous innovation maintains the technological leadership in the field of ammonia synthesis catalysts and provides the latest solutions

- Personalized customization

We provide catalyst solutions based on customer needs to ensure optimal performance.

- Efficient production

Our catalysts support efficient production and improve production efficiency.

- Energy saving and environmental protection

Reduce temperature and environmental impact and promote green ammonia production.

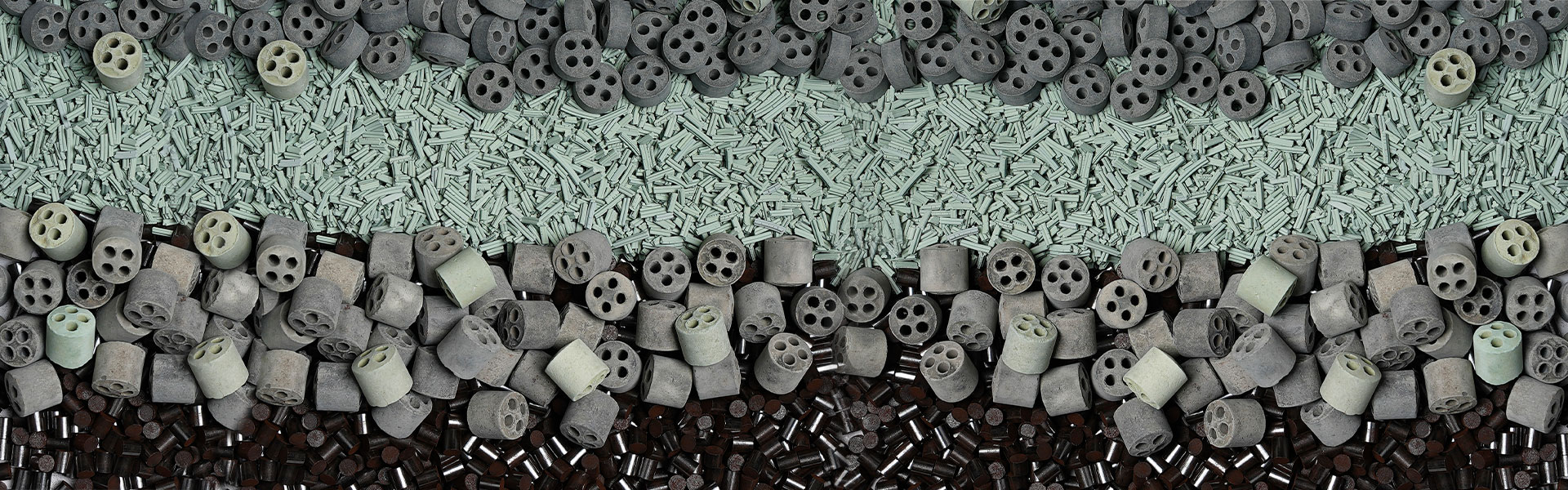

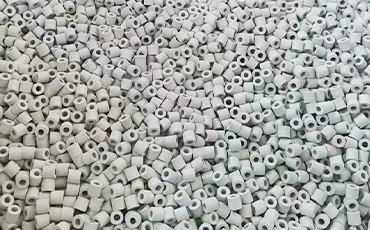

Ammonia Synthesis Reaction Stage Catalyst

Product Grouping

Ammonia Synthesis Process Flow Chart

Working With Syamcat

Marketing Model

- Replacement

Syamcat ammonia synthesis catalyst series can replace Johnson Matthey, Clariant, and Topsoe ammonia synthesis series catalysts. The catalyst performance and service life are equivalent to those of internationally renowned brands, but we can save you more costs and increase a higher ammonia synthesis yield.

View Full Replacement

- Customization

According to your needs, we can provide more distinctive and excellent catalyst products, provide catalyst products that are more suitable for stable operation in extreme or complex environments, and provide design and grading plans for some new projects to provide you with the current operation. We provide technical services for upgrading or improving equipment assembly lines, and can even help you create a new patented product.

View Full CustomizationReliable Ammonia Catalyst Solution

Catalyst solutions

Syamcat utilizes cutting-edge catalyst technology to tailor customized solutions for various needs in hydrogen production plants. Our focus is on optimizing reaction processes to enhance hydrogen yield while minimizing energy consumption during production. Through ongoing research and development efforts, we continuously refine our catalyst formulations to ensure optimal performance under diverse operating conditions. Additionally, we emphasize reducing catalyst usage and extending its lifespan to lower operational costs for our clients. We are dedicated to close collaboration with our customers, understanding their specific requirements, and delivering dependable solutions to achieve mutual production and environmental goals.

Syamcat is committed to providing professional catalyst solutions for ammonia and fertilizer plants. Our catalysts are specifically designed for key reactions in the production of ammonia and fertilizers, aimed at improving reaction efficiency and minimizing energy consumption. Our solutions not only focus on enhancing production efficiency but also strive to reduce waste generation, while adhering to the strictest environmental and safety standards. Through customized technology and continuous research and development, we offer precise solutions to meet our customers' specific production needs and business objectives. We understand the uniqueness of each factory, so our solutions emphasize flexibility and customization to ensure optimal production performance and economic benefits.

Syamcat specializes in providing optimal catalyst solutions for methanol synthesis plants. Our catalyst designs are aimed at optimizing reaction rates and selectivity in the methanol synthesis process, thereby increasing productivity and reducing energy consumption. We are committed to developing innovative catalyst technologies to ensure that our customers' production lines achieve peak performance. Whether it's traditional hydrogenation reactions or new high-selectivity reactions, we can provide reliable solutions to meet our customers' production needs and environmental standards.

Ammonia Synthesis Catalyst Manufacturer

A reliable partner

Reliable Ammonia Catalyst Solution

Catalyze Sustainable Agriculture

Through continuous technological innovation, syamcat provides catalytic solutions for ammonia production. This initiative aims to help ammonia plants and fertilizer manufacturers maximize production efficiency while minimizing adverse environmental impacts. By offering efficient catalysts, syamcat contributes to reducing energy consumption, decreasing waste emissions, and improving product quality during the production process. These measures not only support the sustainable development of the ammonia industry but also make significant contributions to the sustainable development of global agriculture and food security.

30 History of 30 years

20 0Serving 200 units

30 Finished catalyst customized solutions of 30 units

10 Cooperating with 10 research institutes and universities

- Mobile Phone

- *Title

- *Content