Reliable Ammonia Catalyst Solution

Ammonia Plant

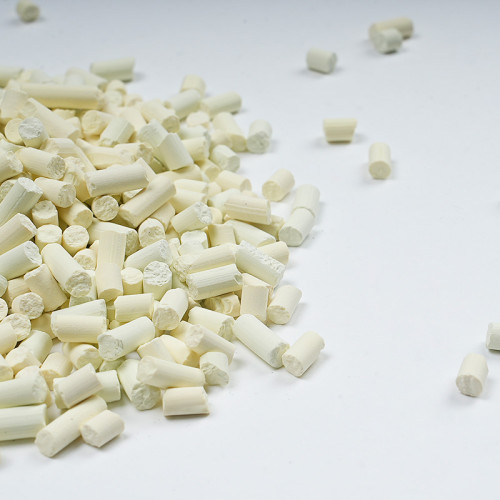

Ammonia synthesis catalyst is a high-performance ammonia catalyst produced by SYAMCAT through optimizing raw material selection, optimizing process conditions, and improving product quality.

In order to meet the diverse requirements of ammonia and fertilizer plants for ammonia synthesis catalysts, SYAMCAT has developed and produced two different states of catalysts: oxidation state and reduction state to serve our excellent customers.

Why Choose SYAMCAT Ammonia Synthesis Catalyst?

20%~30%

Compared with the other same grade catalyst, 20%~30% more active components are added

95%

More than 95% reduction (after reduction)

2%

O₂ content below 2%

8+

8+ years of high guaranteed service life

200℃

Low activation temperature starting from 200℃, which is conducive to operation and cost saving

Production Process of SYAMCAT Ammonia Synthesis Catalyst

① Raw Material Preparation: Magnetite ore is ground and mixed with additives.

② Electromelting: The mixture undergoes electric fusion to transform it into a specific state.

③ Cooling and Pulverization: After fusion, the material is cooled and then pulverized into fine particles.

④ Sieving: The pulverized material is sieved to ensure uniform particle size and consistency.

⑤ Oxidized-State Catalyst: Through the above processes, an oxidized-state ammonia synthesis catalyst is produced.

⑥ Pre-Reduction: The oxidized catalyst undergoes pre-reduction to enhance its properties.

⑦ Passivation Treatment: Passivation treatment is applied to create the final pre-reduced ammonia synthesis catalyst.

② Electromelting: The mixture undergoes electric fusion to transform it into a specific state.

③ Cooling and Pulverization: After fusion, the material is cooled and then pulverized into fine particles.

④ Sieving: The pulverized material is sieved to ensure uniform particle size and consistency.

⑤ Oxidized-State Catalyst: Through the above processes, an oxidized-state ammonia synthesis catalyst is produced.

⑥ Pre-Reduction: The oxidized catalyst undergoes pre-reduction to enhance its properties.

⑦ Passivation Treatment: Passivation treatment is applied to create the final pre-reduced ammonia synthesis catalyst.

Ammonia synthesis catalyst production process flow chart:

Mixing → Electromelting → Cooling → Crushing → Sieving → Oxidation State Ammonia Catalysts → Pre-reduction → Passivation → Pre-reduction ammonia synthesis catalysts

SYAMCAT Ammonia Synthesis Catalyst Solution

In the process of ammonia synthesis, the reaction temperature is increased and the speed of ammonia synthesis is accelerated through the process of gas generation, desulfurization, conversion, purification and synthesis liquefaction.

With the continuous growth in global fertilizer demand, ammonia and fertilizer plants often operate at lower reaction temperatures to remain competitive in the market,which ensures reduced energy consumption and the normal service life of catalysts in ammonia production.

SYAMCAT ammonia synthesis catalyst can reduce energy consumption, enhance efficiency and yield, and effectively lower costs. Furthermore, they have good low temperature activity, obtaining higher ammonia synthesis rate at lower operating temperature and providing a more stable and sustainable production for both ammonia and fertilizer plants.

With the continuous growth in global fertilizer demand, ammonia and fertilizer plants often operate at lower reaction temperatures to remain competitive in the market,which ensures reduced energy consumption and the normal service life of catalysts in ammonia production.

SYAMCAT ammonia synthesis catalyst can reduce energy consumption, enhance efficiency and yield, and effectively lower costs. Furthermore, they have good low temperature activity, obtaining higher ammonia synthesis rate at lower operating temperature and providing a more stable and sustainable production for both ammonia and fertilizer plants.

10 products found

ViewList

SYAMCAT TH18 is a high efficient catalyst to use Pt or Pd precious metal as main active component.

FavoritesModel: SYAMCAT A126

Ammonia synthesis catalyst is divided into oxidation and reduction state to serve our excellent customers.

FavoritesModel: SYAMCAT XT317/SYAMCAT XT318

ZnO Desulfuration Catalyst has deep desulfurization extent, easy to use and high sulfur capacity.

FavoritesModel: SYAMCAT A217/SYAMCAT A217R

Ammonia synthesis catalyst is divided into oxidation and reduction state to serve our excellent customers.

FavoritesModel: SYAMCAT Z433/SYAMCAT Z434

Enhance your ammonia synthesis gas production with SYAMCAT's Primary Steam Reforming Catalyst.

FavoritesModel: SYAMCAT YJ17/SYAMCAT YJ18/SYAMCAT YJ19

Hydrogenation catalyst for hydrogen production with cobalt molybdenum nickel ternary active components.

FavoritesModel: SYAMCAT Z217/SYAMCAT Z218

Enhance your reformer's performance with SYAMCAT's Secondary Steam Reforming Catalyst.

FavoritesModel: SYAMCAT J117/SYAMCAT J118

Methanation Catalyst with Long Service Life for Methanation Process.

FavoritesModel: SYAMCAT B217

Low temperature shift catalyst is taking copper oxide as active component, zinc oxide as structure promoter.

FavoritesModel: SYAMCAT B117/SYAMCAT B117X

High temperature shift catalyst is taking iron oxide as active component, chromic oxide as structure modifier.

FavoritesSYAMCAT's Technology Service of Ammonia Synthesis Catalyst

Customized Catalyst Solutions:

The professional technical team will optimize the synthesis ammonia catalyst according to your operating conditions/requests and propose the most suitable product to you.

Guaranteed 8-Year Service Life:

An official authoritative guarantee of a service life of at least 8 year.

Expert Remote Guidance and Technical Support:

Remote guidance and technical services for catalyst start-up, loading, maintenance of any in-service shutdown, etc. (including reduction). If on-site instruction is required, a small fee will be charged according to the time.

Real-Time Production Monitoring and Support:

Monitor and record data for your production operations at any time (your cooperation is required), and provide real-time technical advice or parameter adjustments if necessary for various conditions during operation.

FAQs of SYAMCAT Ammonia Synthesis Catalyst

- Q:

- Does the ammonia catalyst you produce and supply need to be reduced before using?

- A:

- Normally, for our customers' more convenient use and operation, we directly supply already reduced (reduction state) ammonia catalysts to our customers. It greatly reduces the cumbersome operations and cost consumption during use. If your facility is equipped with a complete reduction furnace, we can also provide you with oxidation state (unreduced) ammonia synthesis catalyst goods, to help you directly control the cost of procurement.

- Q:

- Can you suggest a suitable operating conditions to provide us with a reference?

- A:

- The synthesis ammonia reaction is a chemical reaction of reduced volume. Increasing the pressure will facilitate the ammonia synthesis reaction. But too high pressure will increase power consumption.

Modern ammonia production processes are developing towards low pressure. SYAMCAT synthesis ammonia catalysts have a wide operating pressure range, which can be within the range of 10-40 MPa. Choose the appropriate operating pressure according to your synthesis ammonia process and equipment requirements. Generally, the air velocity is preferably 15,000 to 25,000 h-1 for a small synthesis ammonia tower (φ800mm), 10,000 to 20,000 h-1 for a medium-sized tower, and a lower air velocity for a large tower.

Please send your message to us

SYAMCAT is a professional manufacturer of synthetic ammonia catalysts with over 30 years of catalyst experience and history,Through continuous technological innovation, we offer catalyst solutions for ammonia production.If you would like to learn more or are in search of a manufacturer for synthetic ammonia catalysts for your company, please feel free to contact us.

- Tel

- *Title

- *Content

subscription