Adsorbent Technology Paves the Way for Breakthroughs in Methane Steam Reforming for Hydrogen Production

Introduction to Methane Steam Reforming for Hydrogen Production

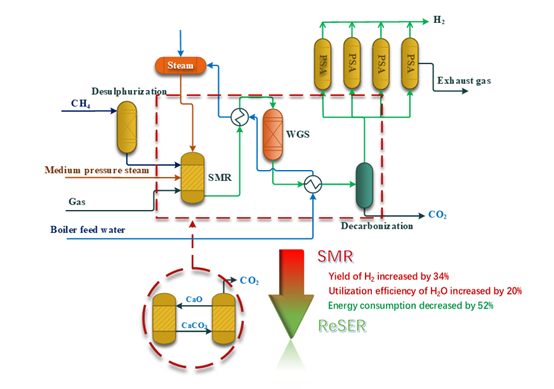

Methane steam reforming is a process where methane reacts with steam at high temperatures to produce hydrogen (H₂). Although widely used, the process requires significant energy to separate CO₂ from the product. CO₂ adsorption-enhanced methane steam reforming combines the reaction and separation processes, reducing energy consumption and allowing for the production of high-purity hydrogen. This also enables lower temperature operation, easing the demands on reforming equipment.

The Role of Catalysts and Adsorbents

Catalysts and adsorbents are key to this process. For catalysts, research focuses on improving methane conversion with highly active, thermally stable, and anti-coking catalysts, mainly Ni-based. Adsorbents, such as CaO-based, lithium salt, and hydrotalcite-based materials, must exhibit high CO₂ capture capacity, stability, and regeneration efficiency.

Types and Performance of Adsorbents

Hydrotalcite-based adsorbents have good stability but limited CO₂ capacity, making large-scale use challenging. Lithium salt adsorbents, like lithium zirconate, perform well at high temperatures but have lower reaction efficiency. CaO-based adsorbents are more economical due to their large capacity and fast absorption rates, despite challenges with performance loss over multiple cycles.

AVANT's Technological Innovations and Future Outlook

AVANT is at the forefront of adsorbent development, leveraging its proprietary technology to provide strong support for its high-efficiency, environmentally friendly catalysts. As AVANT continues to push the boundaries of innovation, the company is committed to enhancing the efficiency and sustainability of methane steam reforming for hydrogen production. For more information, visit our official website at https://www.sd-avant.com/ or contact our customer service team directly.

Together with AVANT, move toward a more efficient and sustainable future!