Efficiency Unleashed: SYAMCAT Steam Reforming Catalysts Transforming Synthesis Gas Production

Efficiency Unleashed: SYAMCAT Steam Reforming Catalysts Transforming Synthesis Gas Production

In the realm of catalytic excellence, SYAMCAT steam reforming catalysts stand out as pioneers in combating carbon deposition challenges. This exploration unveils the unique attributes of SYAMCAT catalysts, showcasing their potential to significantly enhance efficiency in the intricate process of steam reforming.

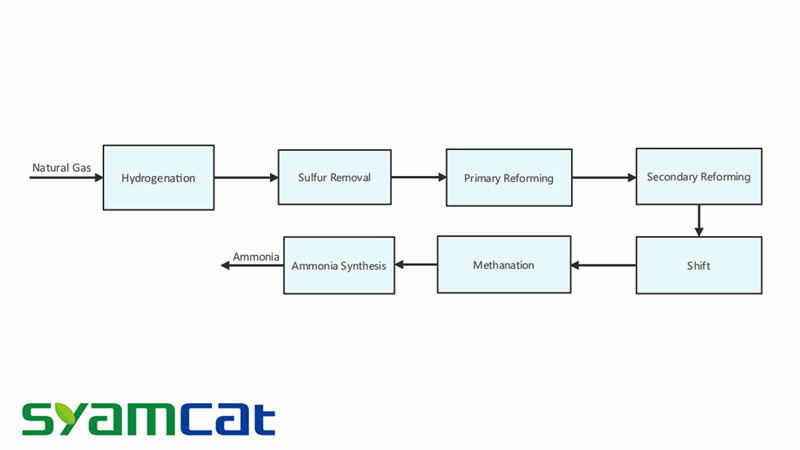

Optimizing the Synthesis Gas Process with SYAMCAT Catalysts

Navigating through the intricate synergy between catalyst selection and operational optimization, this segment emphasizes the pivotal role of SYAMCAT catalysts. By elevating the overall efficiency of synthesis gas production, SYAMCAT proves to be a strategic catalyst choice in the pursuit of process optimization.

SYAMCAT: A Shield Against Deactivation and Carbon Buildup

Delving deeper, we uncover how the exceptional activity and stability of SYAMCAT catalysts act as a shield, effectively mitigating risks associated with catalyst deactivation and the unwanted buildup of carbon on surfaces. SYAMCAT emerges as a safeguard against operational setbacks.

Prolonging Service Life: SYAMCAT's Impact on Conversion Tubes

Shifting focus, we investigate the tangible impacts of SYAMCAT catalysts on extending the lifespan of conversion tubes. This exploration sheds light on how these catalysts minimize thermal cracking, ensuring a longer and more reliable operational life for steam reforming tubes.

Proactive Measures: Maintaining the Optimal Water-to-Carbon Ratio

Venturing beyond catalyst specifics, the article emphasizes the paramount importance of maintaining an optimal water-to-carbon ratio. This proactive measure becomes a key strategy in preventing rapid carbon deposition and sustaining SYAMCAT catalyst performance.

Rigorous Poison Removal: Safeguarding SYAMCAT Catalyst Resilience

Moving forward, we explore proactive measures, with a focus on thorough poison removal to enhance SYAMCAT catalyst resilience. This strategic approach prevents activity decline and safeguards against carbon-related issues, ensuring the longevity of catalyst effectiveness.

Temperature Optimization: Aligning Conditions with SYAMCAT Characteristics

Temperature takes center stage as we unpack the significance of monitoring and fine-tuning temperature distribution. This optimization aligns operating conditions with the unique characteristics of SYAMCAT catalysts, enhancing their performance over time.

Sustainable Operations: SYAMCAT Catalysts and Process Optimization

In a holistic conclusion, we tie together the extended and optimized preventative measures, emphasizing the synergy between these measures and SYAMCAT catalysts. This collaborative approach leads to sustainable and reliable synthesis gas production, highlighting a commitment to efficiency, longevity, and environmental responsibility in industrial processes.

Contact SYAMCAT

If you have specific requirements or inquiries, please feel free to reach out to SYAMCAT. We are here to address your needs and collaborate on tailored solutions to optimize your catalyst procurement experience. Contact us for personalized assistance and discover how SYAMCAT can contribute to the efficiency and sustainability of your ammonia synthesis processes.