Pioneering Ammonia Synthesis Catalysts: SYAMCAT's Revolutionary Advancements

Pioneering Ammonia Synthesis Catalysts: SYAMCAT's Revolutionary Advancements

In a groundbreaking leap towards innovation, SYAMCAT emerges as a frontrunner in the realm of ammonia synthesis catalysts. Fueled by profound chemical research capabilities and forward-thinking technological innovations, the company introduces its next-generation catalysts, set to redefine industry benchmarks and offer efficient, sustainable solutions for ammonia production.

Revolutionizing Chemical Composition Ratios of Ammonia Synthesis Catalysts

SYAMCAT's ammonia synthesis catalysts mark a significant breakthrough in chemical composition ratios. The company's unwavering commitment to meticulous research has resulted in catalysts that not only showcase remarkable performance improvements but also chart the course for a more sustainable future in ammonia synthesis.

Essential Components of Iron-Based Ammonia Synthesis Catalysts

At the heart of SYAMCAT's catalysts lies iron, with magnetite (Fe3O4) as the primary component. The choice of iron as the foundation is deliberate, carefully considered, and scientifically validated, endowing the catalysts with exceptional reaction activity and catalytic performance.

Strategic Design of Active Components

Beyond iron, the catalysts incorporate meticulously measured quantities of cobalt oxide (Co3O4), aluminum oxide (Al2O3), potassium oxide (K2O), calcium oxide (CaO), and other additives. This scientific design enhances the catalysts' performance in ammonia synthesis reactions, amplifying reaction rates and product selectivity.

Precision in Performance Optimization

SYAMCAT achieves targeted optimization of catalyst performance through precise adjustments to the additive ratio. Notably, the catalysts boast a higher K2O content compared to counterparts, proving pivotal in enhancing overall activity.

Innovative Introduction of Cobalt for Enhanced Performance

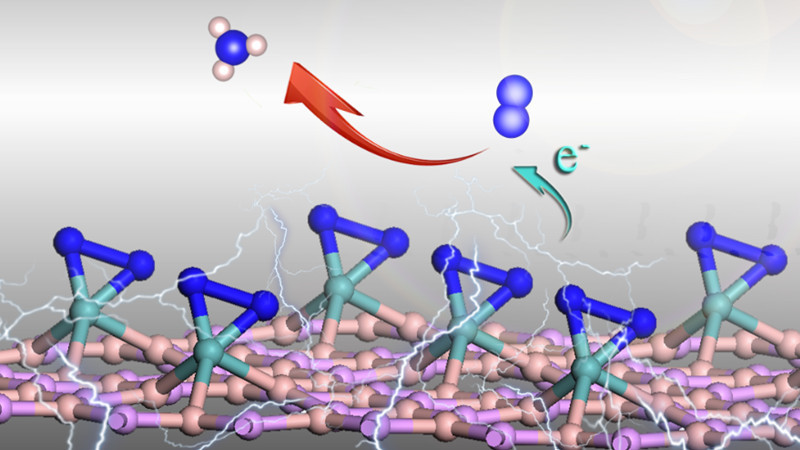

A groundbreaking move for SYAMCAT's catalysts is the introduction of cobalt oxide (Co3O4). This addition, forming a solid solution with magnetite during the melting process, ensures a uniform distribution of iron atoms in α-Fe. This not only reduces the size of α-Fe grains but also improves pore structure, facilitating the transfer of reactants and products, consequently increasing catalyst efficiency.

Thoughtful Use of High-Activity Oxide Additives

SYAMCAT judiciously deploys high-activity oxide additives like cobalt oxide and aluminum oxide. These additives, remaining unreduced during the process, serve to isolate α-Fe, resulting in smaller, more stable grains, further enhancing the catalysts' activity and stability.

Significance for Distributors and Agents

The revelation of SYAMCAT's cutting-edge catalysts holds profound implications for distributors and agents. Armed with a unique selling proposition centered around sustainability and innovation,distributors can leverage these breakthroughs to stand out in the market. The wealth of technical

information enhances credibility, enabling distributors to effectively communicate the advantages of SYAMCAT's catalysts.

SYAMCAT's unwavering commitment to innovation in the ammonia synthesis catalyst arena is set to revolutionize the industry. The fusion of precise chemical composition, strategic additive ratios, and environmental consciousness positions SYAMCAT's catalysts as a guiding light towards a sustainable future in ammonia production. This breakthrough not only elevates product performance but also propels research and technological development in catalysis, promising a more sustainable and environmentally friendly trajectory for the ammonia synthesis industry.

The above briefly introduces “Pioneering Ammonia Synthesis Catalysts: SYAMCAT's Revolutionary Advancements", If you would like to learn more or are in search of a manufacturer for ammonia synthesis catalysts for your company, please feel free to contact us.

SYAMCAT is a professional manufacturer of ammonia synthesis catalysts with over 30 years of catalyst experience and history. Through continuous technological innovation, we offer catalyst solutions for ammonia production. We are dedicated to assisting ammonia plants and fertilizer manufacturers in optimizing production efficiency while reducing environmental impact. Our aim is to contribute to the sustainability of global agriculture and food security.