Maximizing the Service Life of Ammonia Catalysts with Customer-Centric Innovations

Maximizing the Service Life of Ammonia Catalysts with Customer-Centric Innovations

In our unwavering commitment to meet the growing demand for efficient ammonia synthesis, SYAMCAT employs cutting-edge R&D technologies to extend the service life of ammonia synthesis catalysts. Explore the following customer-oriented strategies that focus on improving catalyst stability, activity, and resistance to poisons, ultimately maximizing their service life.

Precision Design of Ammonia Catalyst Active Components

Uncover the heart of the catalyst—the active components. With profound insights into the catalytic characteristics of different metals, we meticulously design the structure of active components to enhance their activity and selectivity in ammonia synthesis reactions.

SYAMCAT utilizes cobalt-based ammonia catalysts, offering superior selectivity and activity even at lower temperatures and pressures. These catalysts exhibit enhanced resistance to poisons, ensuring a prolonged service life.

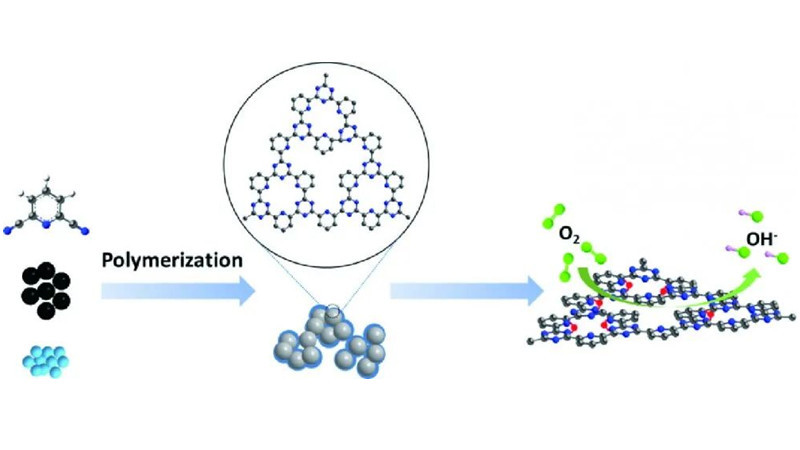

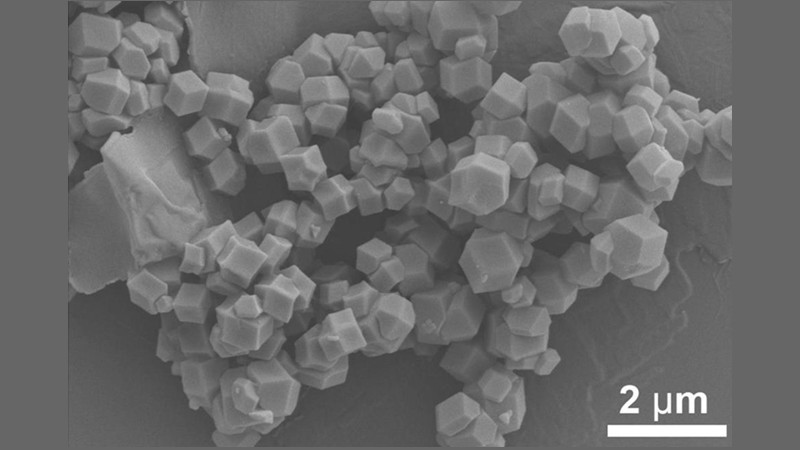

Optimization of Catalyst Carrier and Microstructure Control

A comprehensive exploration into catalyst carrier materials guides us to select carriers with outstanding stability and surface activity. Microstructure control enhances the physical and chemical properties of the carrier, improving the dispersion and availability of active metals. This optimization not only contributes to increased surface area but also fortifies the catalyst's long-term stability.

Application of Surface Modification Techniques

Introducing crucial surface modification techniques involves incorporating specific functional groups or additives on the catalyst's surface. This achieves surface modification of active metals, enhancing resistance to poisoning and coking. This strategy slows down the deactivation rate of the ammonia synthesis catalyst, extending its service life.

Reduction and Regeneration of Ammonia Catalysts

Regular reduction and regeneration operations introduce a reducing atmosphere, aiding in the removal of oxide layers and coke from the catalyst's surface. This restorative step helps prolong the catalyst's service life and enhances stability.

Sulfur and Chlorine Resistance Technologies

Recognizing the potential harmful effects of sulfur and chlorine in the ammonia synthesis process, SYAMCAT has introduced sulfur and chlorine-resistant technologies. By selecting active components and carriers resistant to these elements, we effectively mitigate their corrosive impact on the catalyst, improving durability.

Utilization of Advanced Monitoring Technologies:

Employing advanced online monitoring technologies provides real-time insights into the catalyst's performance. This enables swift identification of anomalies that may lead to deactivation, allowing for timely adjustments to prevent and resolve potential issues.

Through a series of in-depth research and the application of professional technical methods, SYAMCAT continually enhances the performance of ammonia synthesis catalysts. Our goal is to provide customers with more stable and durable catalysts, contributing to the sustainable development of industrial ammonia synthesis. Upholding a spirit of technological innovation, we remain committed to deepening our research and contributing more professional knowledge and technological innovations to the industry.

For more information or if you are in search of a manufacturer for ammonia synthesis catalysts for your company, please feel free to contact us.